MG200 Series / Magnetic Drive Micro Gear Pump (DC brush motor)

1 .Magnetic gear pumps, using magnetic coupling drive without leakage,316 stainless steel shell, PEEK material gear,PTFE materials for the static sealing and bearing, can with the built-in limit pressure valve.

2. Pump can be used in the -0.1 Mpa~2Mpa closed systems, the rated output pressure is 0.5 Mpa (medium: water),the highest output 1 Mpa pressure, flow rate 50~3500 ml / min.

3. Widely used in medical machinery, fine chemicals, water treatment printing, cleaning, packaging, food processing,.and other areas of liquid delivery

Magnetic Drive Gear Pump Features:

1.High differential pressure capability,small size

2.Excellent suction capability

3.Smooth, Pulseless Delivery

4.Easy to Service Chemical resistance

5.DC Motor drive.

6.Stable fluid stream ideal for precision control and analytical applications

7.Excellent for lubrication and recirculation

8.Repeatable and predictable flowrate

9.Reversible

10.Well suited to pumping hazardous or hygeinic fluids

11.Brushless motor Longer life

12.Safer fluid containment

Magnet drive Micro gear pumps Main Application:

• Medical and surgical equipment pump • Hemodialysis apparatus pump

• Laser apparatus pump • Lubrication pump

• Ink-Jet printing systems (CIJ Ink Printers to Paint metering and Transfer applications)pump

• Cooling systems pump • Laboratory instrumentation pump

• Water treatment pump • Sampling pump

• Food processing equipment (Coffee pumps, hot and cold drinks, mixing, milk,and carbonation)pump

• Sanitization pump

• Atmospheric water generator, Atmospheric drinking water devices

Specifications:

| 1 | Motor Type | Brush DC motor |

| 2 | Max flow | 3.5L/min |

| 3 | Max pressure | 10Bar |

| 4 | Rated Voltage | 24V |

| 5 | Suction Height | 1~2M |

| 6 | Fluid Temperature: | -10 ℃ ≤ T ≤ 100 ℃ (except for the freezing) |

| 7 | Pump Theory | Gear pump |

| 8 | Humidity environment: | ≤ 85% |

| 9 | Ambient temperature: | -10 ~ 50 ℃ |

| 10 | Use Place | Indoor |

| 11 | Media: | Most Liquids, acid and alkali, salt, organic solvents, oils. |

| 12 | Fluid viscosity: | 0 ~ 3000 CPS |

| 13 | Ideal Life Time | 1500~2000hours |

| 14 | Working Way | Continous |

| 15 | Weight | 1.5kg |

| 16 | Functions | Can dry-running, Self-priming |

Parameter:

| Model | Max Head Pressure (Bar) | Max Flow scope (ml/Min) | Power (W) | Voltage (V) | Inlet/Outlet Diameter | ml/rpm (reference 3000RPM) |

| MG204XK/DC24 | 10 | 1000 | 70W | DC24 | G1/8” | 0.27 |

| MG209XK/DC24 | 7 | 2500 | 70W | DC24 | G1/8” | 0.55 |

| MG213XK/DC24 | 7 | 3500 | 70W | DC24 | G1/8” | 0.75 |

| Note: 1. "04" means the gear with the height of 4mm, "09" means 9mm, "13" means 13mm . | ||||||

| 2. if needed : "L" limited pressure valve, " R " non return valve , please specially specify in advance. | ||||||

| 3. "XK" PEEK gear, "YT" Alloy gear, if the liquid contain rigid particles,such as pigment ink,recommend use YT gear. | ||||||

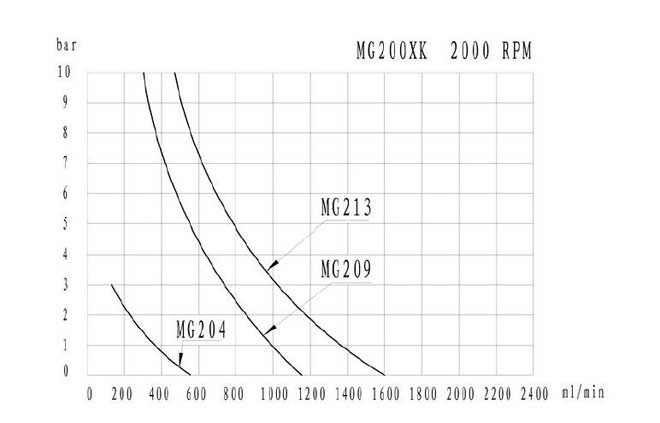

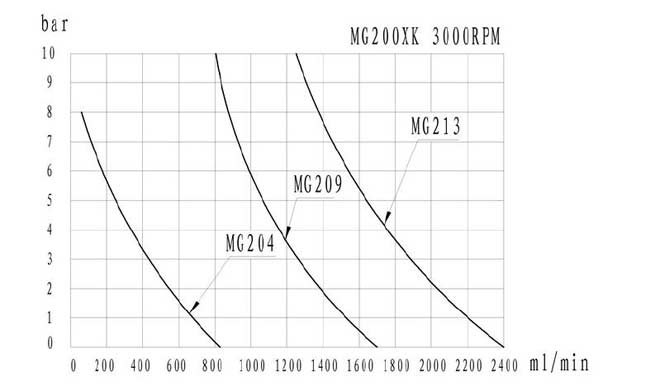

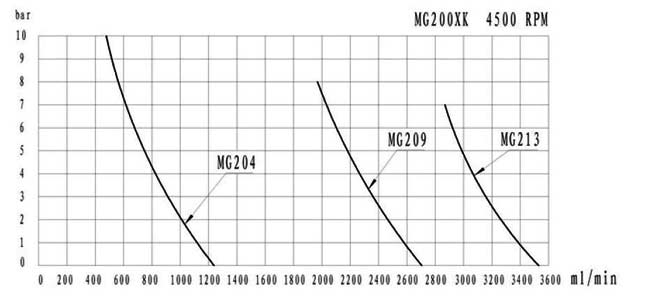

Curve & Dimension:

Note: Usually suggested to work under 4000RPM, not higher than this.

Above test result basis on the medium of water.

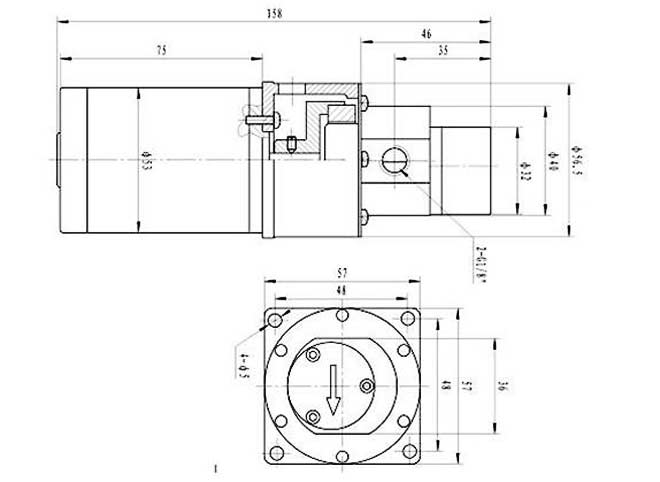

Dimension:

Awaiting for your inquiry, we will response you at the first time!