How to Achieve Precise Temperature Control?

A Comprehensive Guide to the Core Application of PWM Water Pumps in Drinking Water Systems

1. What is PWM Speed Control, and why is it important for DC water pumps?

Answer:

PWM (Pulse Width Modulation) is a technology that precisely controls a DC water pump's speed by adjusting the duty cycle of pulse signals. The principle involves rapidly switching the control signal (typically 100 Hz–100 kHz) to change the on-off voltage ratio per unit time. This enables linear adjustment of water flow rate.

Advantages of PWM over traditional analog voltage regulation:

• High-precision regulation: Duty cycle adjustment ranges from 1% to 100%, with flow rate error within ±5%.

• Ultra-fast response: Flow rate can adjust in under 20 ms, adapting instantly to varying demand.

2. How do PWM water pumps control the temperature in hot and cold water dispensers?

Answer:

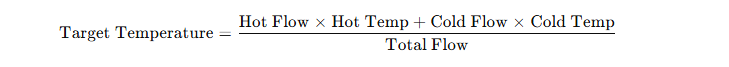

Hot and cold water dispensers achieve target temperatures by mixing hot water from the heating tank with room-temperature water filtered through RO systems. The formula is:

Key points:

• Cold water flow is usually fixed.

• Hot water temperature is relatively constant.

• Hot water flow rate, controlled via PWM pump, is the main variable to achieve precise temperature.

Mechanisms for precise control:

1.Multi-scenario adaptation: The main control chip sends PWM signals based on user-selected output (e.g., 45°C milk or 90°C coffee), adjusting the hot water flow from 500 ml/min to 3.5 L/min. High-quality PWM pumps respond quickly to maintain linear and stable flow rates.

2.Real-time temperature compensation: Built-in sensors detect temperature deviations. The PWM duty cycle is dynamically adjusted via a closed-loop “temperature-PWM” control, ensuring high-precision temperature stability.

3. What factors should manufacturers consider when selecting PWM water pumps?

Answer:

The water pump acts as the “core engine” of the dispenser. Choosing the right PWM pump affects performance, user experience, and lifespan. Key selection criteria include:

3.1 Flow Rate and Head

• Does the pump meet system design requirements?

• Can it maintain stable output under different pipeline resistances?

• Adequate head ensures smooth delivery of hot water; proper flow rate stabilizes temperature mixing.

3.2 High Precision and Linearity

• Is the flow rate accurate under varying duty cycles (e.g., 30%, 50%, 70%)?

• Is the flow rate–duty cycle curve linear?

• Non-linear pumps compromise MCU control, causing temperature inaccuracies.

3.3 Batch Consistency and Stability

• Is output consistent under the same duty cycle?

• Is performance stable across time and different units?

• Ensures reliable product experience and protects brand reputation.

3.4 Response Speed and Reliability

• Can the pump respond quickly to PWM commands?

• Brushless motor designs enhance lifespan and reliability.

3.5 Quiet Operation and Durability

• Is the pump noise low during low/high-speed operation?

• Brushless designs reduce wear, offer quieter operation, and extend service life—especially valuable for night use.

4. Why is PWM speed control a core technology for high-end drinking water systems?

Answer:

PWM water pumps transform dispensers from functional devices into experience-oriented products. They:

• Enable precise flow rate and temperature control.

• Balance temperature and flow through system-level synergy.

• Support high-end product quality, reliability, and user comfort.

|

|

.jpg) |

| Hot water pump TL-B10 | Hot water pump TL-B04 | Hot water pump TL-B03 |

Industry insight:

Topsflo provides intelligent PWM water pump solutions that are linearly precise, responsive, quiet, and durable, enhancing competitiveness for premium drinking water systems.