What should be paid attention to when selecting miniature diaphragm pump?

Before we introduced you to the key points of parameters that need to be paid attention to in the selection of micro brushless DC centrifugal pumps, how to choose micro diaphragm pumps that are also widely used? This article will take everybody to understand what a diaphragm pump is, its characteristics and uses, and the parameters that beginners should pay attention to when selecting models.

What is a Miniature Diaphragm Pump?

Diaphragm pump, also known as membrane pump, is a special form of positive displacement pump. It uses compressed air as power to change the fluid flow with the help of power operation. There is an elastic diaphragm on the eccentric wheel of the diaphragm pump, which uses this elastic diaphragm as the driving force to continuously reciprocate to change the space volume in the pump head to achieve the purpose of conveying various media.

Because the diaphragm pump has the advantages of strong acid and alkali resistance, corrosion resistance, and can be used in various corrosive media. And it is small in size, easy to move, occupies a small area of equipment space, and is simple and convenient to install. Since its birth, it is gradually involved in the market of other pumps, expanding its market share, widely used in medical, beauty, laboratory equipment, biochemical analysis and other industrial applications.

The main basis for the selection of Miniature diaphragm pump

Like other pumps, the main basis for the selection of diaphragm pumps mainly depends on the relevant parameters, characteristics and environmental conditions of the system or equipment. The performance parameters that are mainly referred to when choosing a diaphragm pump include flow rate, working voltage, positive and negative pressure (working pressure), working mode and life expectancy and other considerations.

1. Flow rate of diaphragm pump

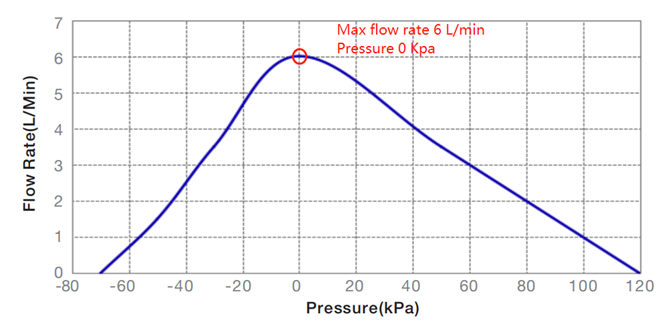

The flow rate of the diaphragm pump refers to the volume flow of various media through the diaphragm pump per unit time. Internationally, units such as L/min and GPM are usually used to describe the flow rate. As shown in the flow and pressure curve of the diaphragm air pump below, the flow and pressure are inversely proportional, and the larger the flow, the lower the pressure. When the air flow reaches the maximum 6L/min, the pressure generated by the pump is 0 kPa. It is not difficult to see from this, because the pressure is 0 kPa, so the diaphragm air pump in the actual working condition, generally will not output the maximum point of flow, but according to the actual working condition required flow and pressure to choose.

2. Positive and negative pressure of diaphragm pump

Positive pressure refers to the pressure higher than the normal pressure (that is, standard atmospheric pressure) gas state. It may not be easy to interpret "higher than normal pressure" literally, but we can translate it into positive pressure, which is the constant flow of gas into a space. For example, it is common in life to use air tools to inflate balloons, car and bicycle tires, and the end that produces the gas is positive pressure.

Negative pressure is a gas state lower than normal pressure. Contrary to positive pressure that continuously transports gas into space, negative pressure continuously extracts gas into space, which we call vacuum. The use of negative pressure is very common. For example, in common vacuum storage, air is pumped out the storage bag through a diaphragm pump. At this time, the storage bag is completely sealed, and the gas inside is drawn out by the diaphragm pump, and negative pressure is formed in the bag. When people breathe, the alveoli expand, creating negative pressure, and the pressure difference between the inside and outside of the lungs pushes fresh air into the lungs.

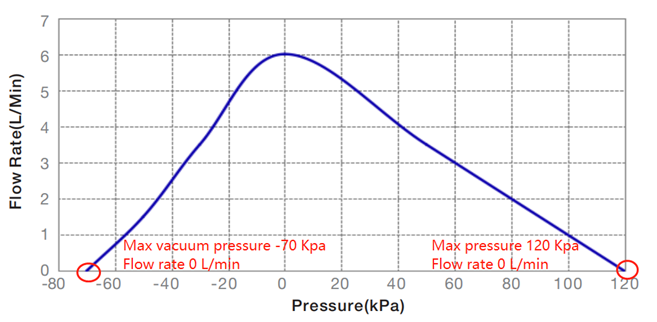

Because of the characteristics of positive and negative pressure, diaphragm pumps are also widely used in medical gas treatment, such as ventilators, nebulizers and other medical equipment are designed on this principle. The international usually use kPa, Pa, mmHg or cmHg and other units to describe the working pressure of the pump. Taking the flow pressure curve of diaphragm air pump as an example, when the flow rate is 0L/min, the maximum vacuum degree of pump is -70 kPa, and the maximum pressure is 120 kPa. However, because the rated pressure of diaphragm pump is limited. In order to ensure the personal safety of equipment and operators, and do not damage the performance of the pump, diaphragm pump in the use of the need to pay attention to the intake pressure does not exceed the maximum allowable use of the pump pressure.

3. Working voltage of diaphragm pump

The voltage of diaphragm pump mentioned in this article refers to DC voltage, which is generally divided into 12V and 24V. We can choose different voltages according to the power supply parameters of the equipment or system, but the pump must be within the operating voltage range during operation, because whether the operating voltage is high or low, long time in this voltage environment will cause certain damage to the diaphragm pump.

4. Working mode and service life of mini diaphragm pump

Because of the different composition structure and working principle, diaphragm pump is divided into brush motor and brushless motor, the difference between the two is reflected in the working mode and life of the pump. Brush motor is suitable for intermittent work, and the service life is not high requirements of the working environment. Brushless motor is suitable for continuous work, and the service life has certain requirements of the working environment. TOPSFLO's brushless diaphragm pump series adopts high-grade hollow cup slotless motor and double ball imported bearings. The overall performance is stable, the noise is as low as 50dB, and the motor life is as long as 15,000 hours, far exceeding the domestic market counterparts in the brushless 5000 hours life and noise standards of 70dB.

5. Precautions for diaphragm pump use

Since the motor of the pump is exposed to air, in order to avoid affecting the operation of the motor, the pump needs to be installed in a dry environment. And diaphragm air pump without any treatment operation, can not work in flammable and explosive environment, and air pump in the extraction of harmful gas, we must carry out a secondary seal on the whole pump, to ensure personal safety.

Selection principles of high quality miniature diaphragm pump

To sum up, the selection of diaphragm pump should meet the requirements of flow, pressure, working mode and expected life required under actual working conditions, so that the pump can run in the high efficiency interval of parameters for a long time. After nearly 20 years of technology precipitation, TOPSFLO has developed and produced TM micro diaphragm gas pumps and TF series of micro diaphragm liquid pumps, which adopt self-developed and designed high-performance motor, imported bearings, imported rubber diaphragm, patented diaphragm structure and heat dissipation structure, and have EPDM, PTFE valve plate, EPDM, FPM diaphragm optional, with high chemical corrosion resistance performance. Wear resistance and heat dissipation performance than the market peers more outstanding. The overall performance and life of the product has greatly exceeded the domestic industry standards, and can be comparable with foreign KNF, Parker, Thomas brand pumps, and can be used as a good substitute for similar.

In addition, when selecting suitable and satisfactory pumps, we should pay attention to the supplier's qualification, such as the supplier's R&D and manufacturing capability, production quality control, system management ability and international certification, etc. TOPSFLO is the first national high-tech enterprise to pass TÜV ISO 9001 & IATF 16949 double quality system certification in the micro DC pump industry, and maintains long-term strategic partnership with many international famous brands. All products are independent research and development design, with more than 20 years of industry experience of the R & D engineer team, has more than 10 years of experience in core customer customization development, can provide efficient professional customized solutions or new design and development solutions for global customers in various industries.