How to choose a micro air pump? these three parameters are very important

The micro diaphragm air pump is a small size gas transport instrument with high efficiency and low noise, and has become an indispensable tool in many fields, such as medical treatment, biology, and manufacturing.

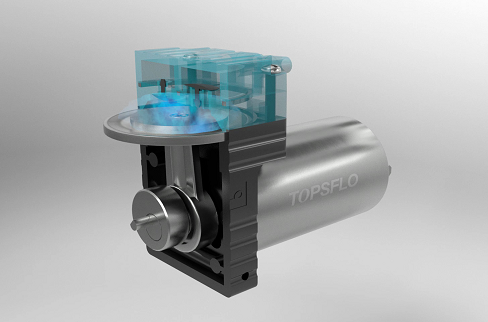

The micro air pump is usually composed of a motor, an air chamber, a control unit, and appropriate pipes and valves. It works similarly to a traditional gas compressor, but with a smaller size and higher precision, it can get gas into very tight spaces.

There are all kinds of micro air pumps on the market, how should we choose as a novice? Generally, we can judge from the following parameters:

1. Positive pressure

The micro air pump positive pressure test is a common method to detect the performance of the air pump. Connect the outlet of the air pump to the detection container, turn on the power supply, and continuously exhaust gas into the container. When the air pressure in the container does not rise and maintains a certain value for a certain period of time, this value represents the ultimate pressure value of the pump.

When performing a positive pressure test, it is necessary to pay attention to controlling the exhaust volume of the air pump to ensure the accuracy of the results. At the same time, factors such as the pressure stability and pressure fluctuation of the air pump, and the response speed to different pressure values also need to be considered. Through comprehensive consideration of these factors, the performance of micro air pumps of different models and brands can be more accurately evaluated and compared.

2. Negative pressure

During the use of the micro diaphragm vacuum pump, negative pressure is an important parameter, which reflects the pumping capacity and vacuum degree of the micro air pump. Usually, the measurement of negative pressure needs to connect the inlet of the air pump with the detection container, and then turn on the power supply to pump the inside of the container for a long time. When the gas pressure in the container no longer drops and remains at a certain value for a certain period of time, we can get the ultimate vacuum value of the mini air pump.

For different application scenarios, it is necessary to select a suitable air pump, and at the same time, it is necessary to consider whether the negative pressure value of the air pump can meet the requirements. Generally speaking, the higher the negative pressure value of the air pump, the stronger its pumping capacity and the higher the vacuum degree.

3. Air flow rate

The air flow rate refers to the volume of air passing through the suction port of the air pump per unit time. During the working process of the air pump, the flow rate is usually an important parameter, which determines the pumping speed and efficiency of the air pump.

Take TOPSFLO's TM30-A12-A01-V7006 Micro Diaphragm Vacuum Pump as an example, its maximum gas flow rate is 6L/min. When the inlet of the air pump is connected to the airtight container, the air pump will continuously extract the gas in the container, so that the pressure inside the container will gradually decrease, and finally reach an absolute pressure of 70KPa.

The size of the gas flow directly affects the pumping rate of the air pump and the change of the gas pressure inside the container. TOPSFLO's TM30-A12-A01-V7006 Micro Diaphragm Air Pump has a large gas flow rate, which can meet most occasions that require efficient pumping, such as laboratory gas collection, gas detection, etc.

It should be noted that in practical applications, the air pump usually needs to be connected with other components (such as pipes, valves, flow meters, pressure gauges, etc.). The existence of these components will affect the flow and pressure of the air pump, so these factors need to be considered when selecting the model. Specifically, we need to leave a margin on the operating point parameters according to the resistance of the air system to ensure that the air pump can work normally and meet actual needs.

In addition to the flow rate and pressure, we also need to consider the head, power, noise, life and other parameters of the air pump. At the same time, in the actual operation process, it is also necessary to regularly check the performance and maintenance of the air pump to ensure its long-term stable operation.

In short, when purchasing a micro air pump, we need to choose a suitable air pump according to the specific application scenario, and consider various factors comprehensively to ensure that the air pump can meet our needs.