What Fast Changes does "Liquid Cooling" Technology Bring to Charging Stations

Recently, Have you noticed that Huawei's "liquid-cooled 600kW supercharger station" caused tremendous repercussions on the internet? It is said that this charging station can achieve a "one kilometer per second" charging speed, providing car owners with a charging experience of "having a cup of coffee and setting off fully charged". This resolves many of the core pain points such as range anxiety and charging anxiety for electric vehicle owners, bringing a completely new charging experience.

Huawei Technologies plans to install 100,000 EV DC fast charging stations in more than 340 cities and major highways across the country in China by 2024, leading the way in achieving "high-quality charging wherever you're"

What is the Liquid Cooling Fast Charging Station?

Different from traditional air-cooled charger, liquid cooling technology utilizes liquids to dissipate heat and maintain equipment temperature. Liquid-cooled ultra fast charging stations use this technology to charge electric vehicles in a shorter period, effectively improving charging efficiency and speed.

First, let's understand the basic principles of liquid cooling fast charging technology. According to the formula "power = voltage x current" (P = UI), we can see that when either the voltage (U) or the current (I) increases, the power (P) will increase, accelerating the charging speed and reducing the time required to fully charge.

Therefore, achieving high power fast charging mainly involves two methods. Firstly, increasing the vehicle's charging voltage—the charging voltage for electric vehicles has transitioned from the previous 400V to 800V and 1000V. Secondly, increasing the charging current. The majority of third-party universal fast chargers in China have achieved the 250A current limit recommended by the 2015 national standard. However, vehicle manufacturers' self-built super-fast chargers can successfully surpass the 250A current limit, achieving a higher 600A current output.

Why Do Electric Vehicle Charging Stations Heat Up So Much?

When the current passes through the resistor, all the electrical energy consumed on the resistor is converted into heat energy. According to Joule's law (Q=I²RT), the heat generated by the current through the conductor is proportional to the second square of the current, proportional to the resistance and power-on time, that is to say, the greater the current, the more heat generated by the charging pile.

Under the premise of the same resistance and equal time, when charging at 250A, a single charging cable or two charging cables can generate 62,500 joules of heat. And when charging at 600A will generate 360,000 joules of heat. Thus, how charging stations can withstand such high levels of heat has become a technical challenge that charging station manufacturers need to overcome.

How to Achieve the "Black Technology" of Liquid Cooling EV Fast Charging?

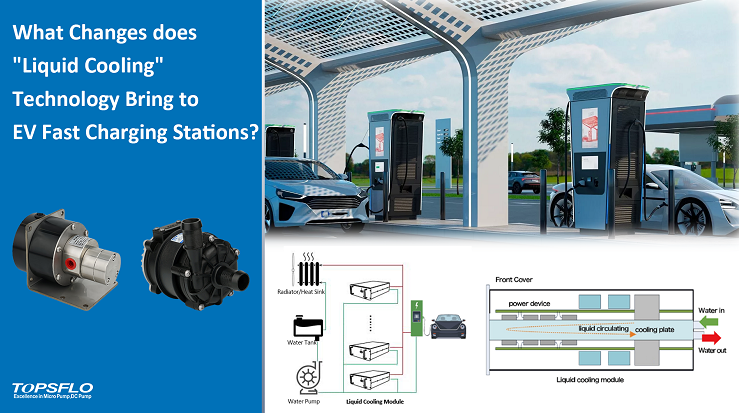

In the liquid cooling EV fast charging technology, the role of the liquid-cooled pump is crucial.This is because the all-liquid-cooled charging station uses a liquid-cooled charging module, with no air ducts on the front and back of the liquid-cooled module. The module relies on the internal circulation of the coolant in the liquid cooling plate to exchange heat with the outside. The heat dissipation liquid is circulated between the charging host and other components to stabilize the temperature and ensure that the charging process is efficient and stable.

Meanwhile, the fully liquid-cooled charging pile has a special liquid circulation channel between cable and charging gun. Liquid coolant for heat dissipation is added to the channel, and the coolant is circulated through a liquid-cooled pump, thereby dissipating the heat generated during the charging process. The liquid cooling system extends from charging station to charging cable and connector, enabling low-temperature operation of the entire charging system. This enhances the heat dissipation performance, increases the device power density and output power, and is significantly improved compared to traditional air-cooled heat dissipation technology.

How to Choose a Good and Reliable Water Pump Manufacturer?

1. Check the qualifications of liquid cooling pump manufacturers:

TOPSFLO has focused on micro pumps for 19 years. The industries we mainly serve are automobiles, charging station liquid cooling systems, home appliances, medical and ect.. 80% of our liquid cooling pumps are exported to European and American high-end markets, with international trademarks from the United States and the European Union. We has a modern factory with 16,000 square meters. Also has a patch factory and an injection molding factory with all imported equipment, an ESD anti-static control digital dust-free workshop, and fully automated electronic lines, motor lines, and water pump assembly and testing line and etc..

2. Whether the water pump has passed strict certification?

TOPSFLO is the only enterprise in China certified by German Rheinland TÜV double quality system of ISO 9001 and IATF:16949 in the micro pump industry. Based on this standard, TOPSFLO strictly controls all aspects of water pump R&D and design, raw material procurement, and production processes. Pursue and achieve "zero defects" in quality.

3. Successful customer cases

TOPSFLO is one of the earliest domestic micro-pump companies to enter the field of liquid-cooling applications for charging piles, and occupies a large market share in the field of liquid-cooled pumps for charging piles. Since 2015, the company has provided 300,000 liquid-cooled water pumps to world-renowned electric vehicle and energy companies, and has professional and mature liquid-cooling solutions for fast charging piles.